Electroless vs Electrolytic Nickel Plating

Electrolytic nickel plating uses a cathode and an anode to electrolyse the solution and begin the process. This means it can only be used on conductive materials, such as steel, copper and brass. Electrolytic plating also does not always offer a uniform finish, requiring wider tolerances.

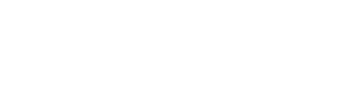

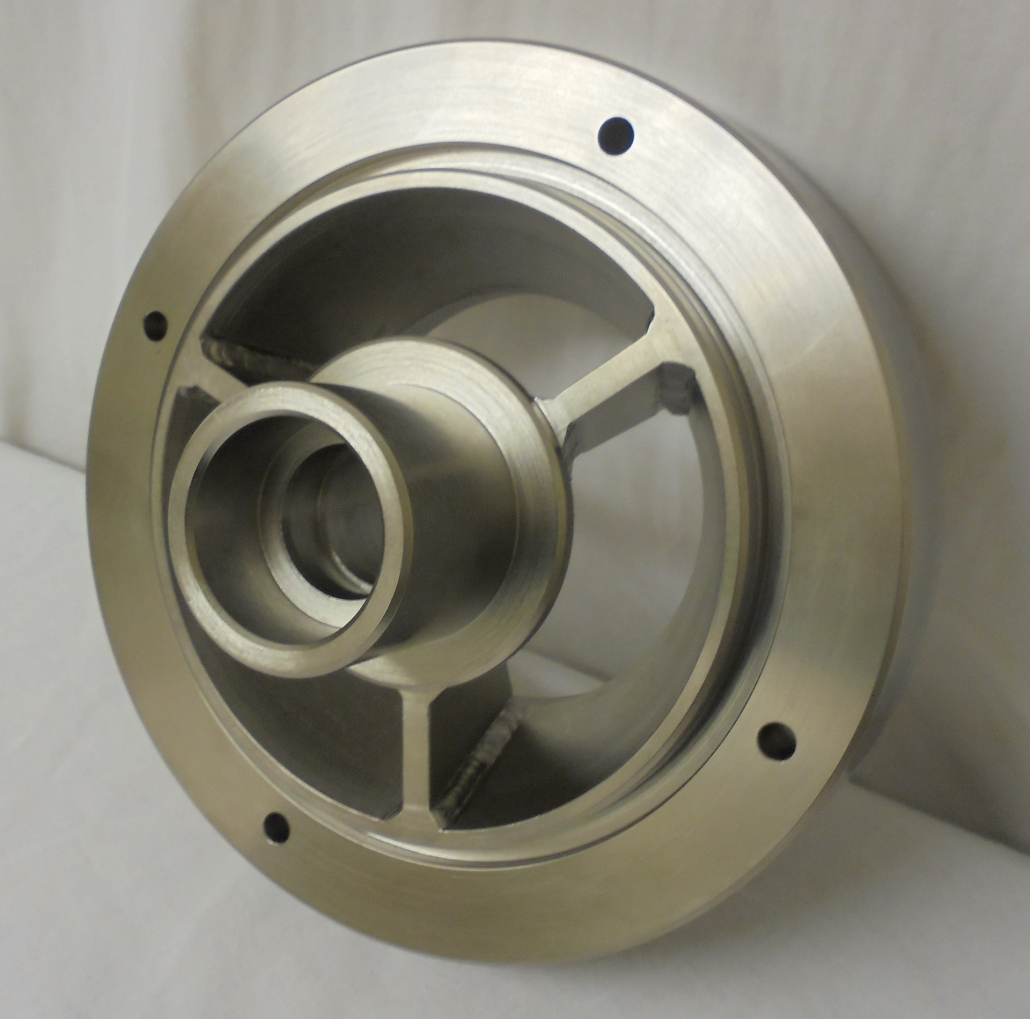

Electroless nickel plating provides a completely uniform finish in all crevices and exposed surfaces, no matter how complex the component’s configurations.

ENP can also be used to improve the surface of a component, to provide a regular surface for desired finishes, or to add a conductive coating to a non-conductive part.

Electroless Nickel Plating Advantages

Medium Phosphorus Electroless Nickel Plating has many advantages over other electroplating methods.

ENP provides a uniform coating, with no deviation in plating thickness across the entire surface, regardless of shape.

The nickel-phosphorus alloy coating has excellent corrosion resistance, perfect for marine use and in oil and gas systems.

Nickel alloy has good hardness and wear-resistance can be further hardened with heat treatment processes post-plating.

Because electroless nickel plating provides a completely uniform coating, it imparts a low friction coefficient to the component. This is fantastic for automotive and manufacturing components.

Electroless Nickel plating can plate to tight manufacturing tolerances, because we can accurately measure the thickness of nickel being plated onto a component. We regularly check the thickness during plating using our XRF machine, and analyse our plating solution’s additions, pH and temperature to estimate the appropriate timings. When the desired thickness is reached, we stop plating.

Suitable Substrates for ENP include: aluminium alloys, copper, steel, and stainless steel.

Get a quote