What is Black Chrome Plating?

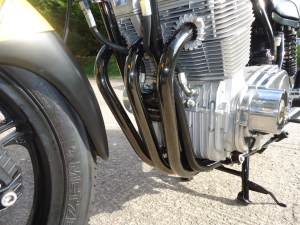

Black chrome is an attractive finish that, once plated, has a layer of oil applied, adding protection and a smooth, silky finish. This plating is corrosion resistant and heat resistant up to 300°C.

Like bright chrome, a black chrome plating service involves electroplating chromium over an initial layer of bright nickel or copper.

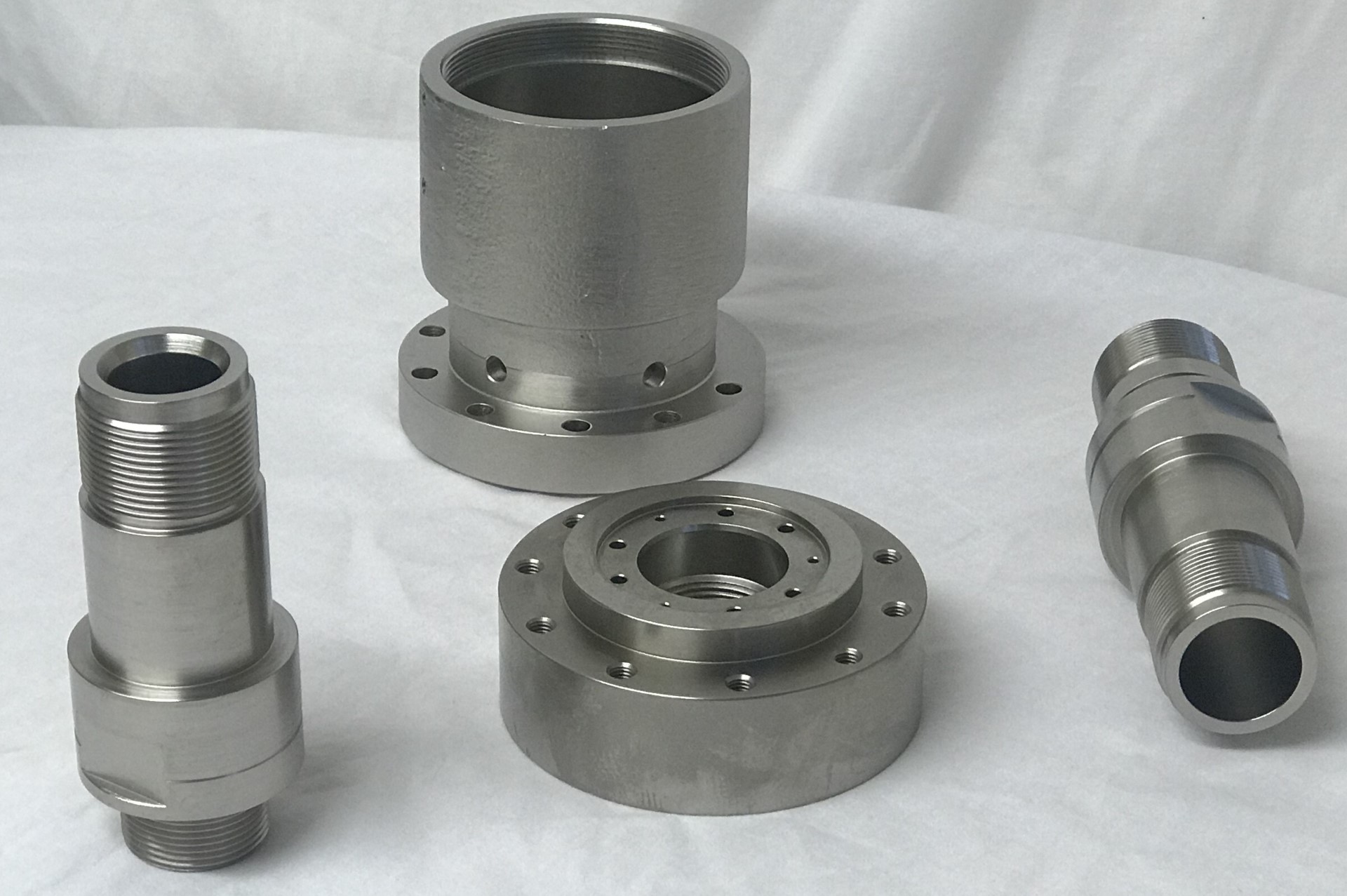

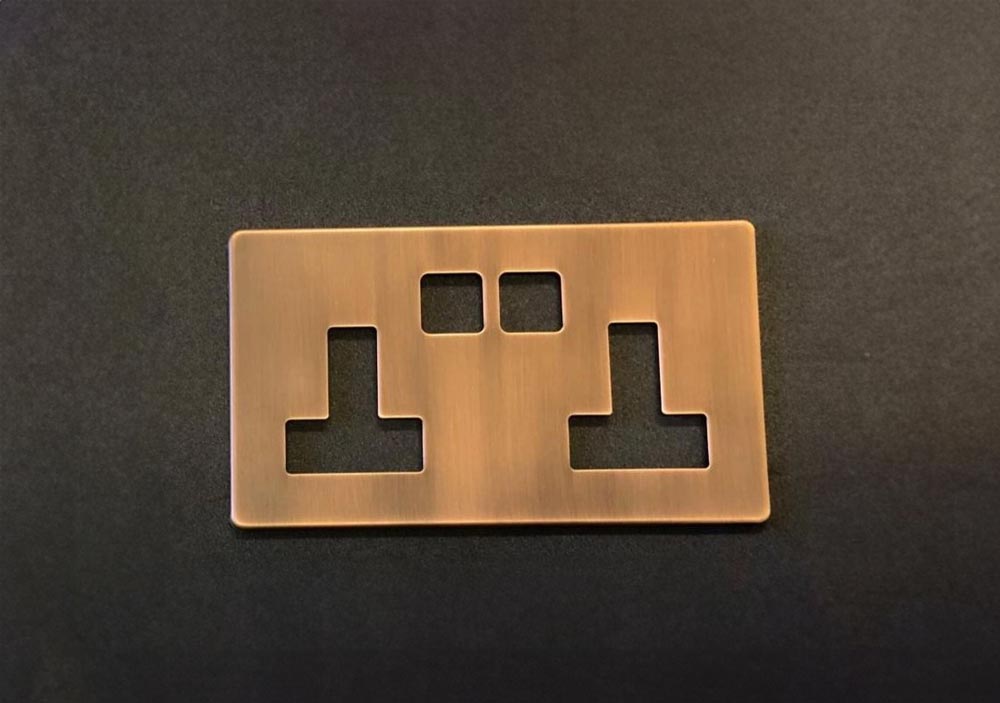

A black chrome finish can be applied to:

- Brass

- Mild Steel

- Stainless Steel

- Aluminium

- Iron

We provide commercial black chrome services for large batch fabrication in automotive, aerospace, furnishings and other sectors.

Black chrome is available in gloss, satin, or matte finishes. Many manufacturers choose this finish for its aesthetic properties, but with high absorbance in the solar spectrum, black chrome plating is also valuable for optics, defence, aerospace and space applications. The finish is also durable and corrosion-resistant, protecting components from rust, weathering and wear.